Introduction

From household appliances to high-performance aerospace equipment, electric motors power our world. Yet, one of the most crucial and often overlooked components inside these motors is the winding—a sophisticated system of coils and wire that enables magnetic fields to drive motion.

Understanding motor winding is key to improving motor efficiency, reliability, and performance, especially in advanced industries like aerospace, energy storage, and medical technology.

In this guide, we’ll break down what motor winding is, how it works, the different types used today, and how modern winding machines—like those produced by industry leaders such as grwinding.com—are shaping the future of electromechanical systems.

What Is Motor Winding?

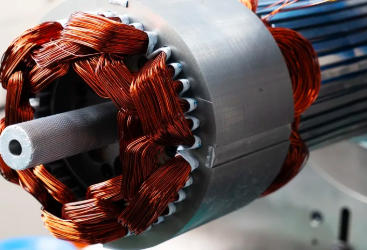

Motor winding refers to the coils of insulated wire placed in the stator or rotor of an electric motor. When electric current passes through these windings, it creates a magnetic field that interacts with the magnetic field of the rotor, causing rotation.

There are two major components in a motor where winding occurs:

Stator Winding – stationary part of the motor

Rotor Winding – rotating part of the motor (not always wound in certain types, like induction motors)

The configuration and quality of these windings have a direct impact on motor torque, speed, and energy efficiency.

Why Motor Winding Matters

Motor winding isn’t just a technical detail—it’s a performance driver. Here’s why it’s essential:

�� Affects Motor Efficiency – Better winding patterns reduce energy loss.

⚙️ Controls Torque and Speed – Determines how power is delivered.

�� Manages Heat Dissipation – Good winding reduces overheating risk.

�� Enhances Lifespan – Quality winding leads to longer-lasting motors.

Whether in a robotic arm, an electric car, or an MRI machine, precision winding is crucial for safe and reliable operation.

Key Motor Winding Types

There are several motor winding configurations, each with unique properties:

1. Lap Winding

Used primarily in DC machines, lap winding connects coils in parallel. This results in multiple paths for current and is ideal for low voltage and high current scenarios.

2. Wave Winding

In contrast to lap winding, wave winding connects coils in series, making it suitable for high voltage, low current applications.

3. Concentrated Winding

Here, all coils of a phase are wound on a single tooth. It’s compact and efficient but can have higher harmonic losses.

4. Distributed Winding

Coils are spread across multiple slots, resulting in smoother torque and reduced harmonics. Widely used in AC induction motors.

5. Random vs. Needle Winding

Used in smaller motors like those in medical devices or electronics. Precision is key, and machine automation ensures consistency.

Advanced Winding Techniques and Automation

Modern motor winding has evolved beyond manual labor and into the realm of precision automation. Manufacturers like Guangri Electronic Machinery Co., Ltd, creators of cutting-edge winding machines, are pioneering this field.

Some of the latest innovations include:

�� CNC-Controlled Winding

Computer-controlled machines allow exact placement of wire, tension control, and layering, ensuring repeatability and accuracy.

�� Multi-Axis Servo Winding

Enables complex winding patterns for customized coil geometries—ideal for aerospace or high-frequency applications.

�� Vision-Based Inspection Systems

High-speed cameras detect any inconsistencies or defects in the winding process, improving quality assurance.

⚡ High-Speed Spindle Winding

Designed for large-scale production, especially for automotive motors and energy storage systems.

Applications Across Modern Industries

Let’s explore how motor winding plays a pivotal role in some of the world’s most advanced technologies.

��️ Aerospace

Aircraft systems require motors that can operate under extreme conditions—temperature fluctuations, vibration, and electromagnetic interference. High-precision motor winding ensures minimal signal distortion and superior reliability.

Common applications:

Actuator motors for flaps and landing gear

Gyroscopic control systems

Electrical pumps and fans

�� Medical Technology

Miniature motors power devices such as insulin pumps, prosthetic limbs, and robotic surgery arms. Here, needle winding and micro-coil winding come into play—requiring extreme accuracy, something made possible by machines from .

�� Energy Storage and EVs

Electric vehicles and battery storage systems rely heavily on efficient motors. The winding must be optimized for minimal energy loss and maximum torque.

Trends include:

Hairpin winding for high current densities

Slotless winding for improved cooling

High-fill factor windings for compact designs

�� Industrial Automation

In factory environments, motors run conveyor belts, robotic arms, and precision tools. The demand here is durability, high efficiency, and ease of maintenance.

Challenges in Motor Winding (And Solutions)

Even with automation, winding presents unique challenges:

| Challenge | Solution via Automation |

| Inconsistent wire tension | Automated tension controllers |

| Manual errors and misplacement | CNC and servo-controlled machines |

| Slow production times | Multi-spindle, high-speed winding systems |

| Lack of customization | Software-controlled pattern generation |

By investing in advanced machinery like those offered by Guangri Electronic Machinery Co., Ltd, manufacturers can overcome these hurdles and achieve consistently high-quality results.

How to Select a Motor Winding Machine

Not all winding machines are created equal. Here’s what to look for:

Customization Options – Can the machine be adjusted for different motor types?

Speed and Precision – How fast can it wind without compromising quality?

Software Control – Does it come with intelligent software for coil pattern management?

Maintenance and Support – Is the manufacturer reliable and responsive?

Application Versatility – Can it be used for various industries?

For businesses aiming to scale their motor production or enhance precision, working with an established manufacturer like can provide a strategic edge.

Future of Motor Winding Technology

As technology continues to advance, so too will motor winding techniques. Here’s what the future might look like:

AI-Driven Coil Optimization

Use of artificial intelligence to determine optimal coil geometries based on application.

Sustainable Materials

Eco-friendly insulation and recyclable core materials.

Zero-Defect Manufacturing

Advanced machine learning and real-time defect detection will minimize product waste.

Fully Autonomous Factories

Lights-out production lines where winding, testing, and packaging are all automated.

Conclusion

Motor winding is the heartbeat of modern electric motors. Whether it’s powering a drone, saving lives through robotic surgery, or driving the electric vehicle revolution, the importance of quality winding cannot be overstated.

For manufacturers and engineers looking to stay ahead in an increasingly electrified world, investing in advanced winding solutions is key. Companies like Guangri Electronic Machinery Co., Ltd provide the precision, customization, and innovation needed to meet the demands of the future.

Discover more about their cutting-edge technology and how it can revolutionize your production process at grwinding.com.

Related Articles

How to Choose the Best Mixer for Your Kitchen Needs

Red Dot Sights vs. Holographic Sights: Key Differences and Benefits

Famousparentings .Com – Your Go-To Guide For Smart Parenting!